This liquid soap making machine is designed to meet GMP standards, offering a professional solution for producing high quality liquid soap, shampoo, dish wash and similar formulations. Constructed from premium 316L stainless steel, it features a double jacketed structure that supports both electric and steam heating options for precise temperature control. The liquid soap manufacturing machine integrates advanced Germany Fluko mixing technology to ensure efficient, uniform blending of ingredients. With its hygienic design, corrosion resistance, and reliable performance, this liquid soap manufacturing equipment is ideal for liquid detergent, shampoo, dishwashing and personal care production.

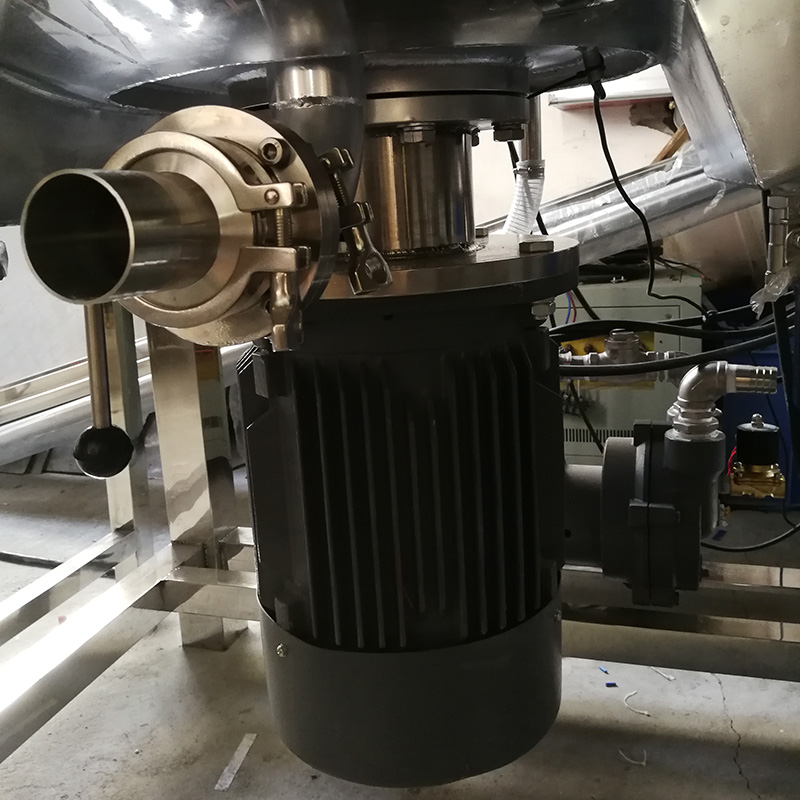

Brand Motor

Upper mixing motor and bottom homogenizer make pretty fine and smooth product with high gloss. The motor adopts ABB or Siemens brand. Electric heating or steam heating is optional.

Homogenizer

To mixing, blending and homogeneous the material when rotating in the homogenizer, widely used in industrial production for emulsification, homogenization and mixing.

Control Box

The PLC automatic control box includes temperature control, frequency control and time setting control. This make you reduce numbers of labors and ensure the quality of products.

Technical Parameters

| Capacity | 10-1000ML customizable |

| Structure | Mixer motor, mixing tank, heating/cooling system,electric box |

| Tank Body | 3 layers of stainless steel mixing tank |

| Material | Internal Layer(Material Contact Part): SUS316L / thickness: 4mm |

| Jacket Layer(Heating/Cooling System): SUS304 / thickness: 4mm | |

| External Thermal Insulation Layer: SUS304 / thickness: 2.5mm | |

| Stirring Method | Using anchor type scraping mixing |

| Mixer Motor(with frequency convertor) Power: 1.5KW | |

| Stirring Speed: 0-60 RPM | |

| Stirring Paddle Material:SUS316L | |

| Homogenizer | Bottom type inner circulation homogeneous form |

| Homogenizer Motor Power:4KW | |

| Homogenizer Rotation Speed: 0-3000 RPM | |

| Homogenizer Material:SUS316L | |

| Open Way | Unilateral portable cover open (activity cover) |

| Additional Capabilities | Heating or cooling |

| Temperature Display | Electric heating temperature meter |

| Pressure | Jacket design pressure 0.1 Mpa |

| Spare Parts | Electric control box, pipe for feeding(Suck) material, support holder |

Features of Liquid Soap Making Machine

-

GMP Standard

Built in accordance with Good Manufacturing Practices, ensuring high-quality output and regulatory compliance for cosmetic and pharmaceutical applications.

-

Germany Fluko Technology

Equipped with advanced mixing technology from Germany Fluko, guaranteeing efficient, uniform, and stable product blending.

-

Customizable Capacity

Available in a range of sizes to suit small-scale labs or large-scale industrial production, tailored to your manufacturing needs.

-

ouble Jacketed Design

Designed with double-layer structure that supports both electric and steam heating for precise temperature control and energy efficiency.

-

Hygienic Design

Internal mirror polishing surfaces and sanitary fittings to ensure contamination free production, meeting stringent hygiene requirements.

Applicable Industries of Liquid Soap Manufacturing Equipment

1. Personal Care & Cosmetics Industry

- Hand sanitizers & liquid soaps

- Body washes & shower gels

- Shampoos & liquid conditioners

- Facial cleansers & makeup removers

- Shaving foams & gels

2. Home & Commercial Cleaning Industry

- Dishwashing liquids

- Laundry detergents

- Floor & surface cleaners

- Car wash shampoos

- Disinfectant solutions

3. Hospitality & Healthcare Sector

- Hotel amenity products (bath gels, hand soaps)

- Hospital-grade hand sanitizers

- Medical facility disinfectants

- Food service cleaning solutions

4. Industrial & Institutional Applications

- Factory floor cleaners

- Vehicle cleaning products

- Agricultural cleaning agents

- Food processing sanitizers

5. Private Label & Contract Manufacturing

- Custom formula liquid soaps

- White-label hygiene products

- Boutique cosmetic cleansers

Reviews

There are no reviews yet.