This liquid soap making machine is designed to meet GMP standards, offering a professional solution for producing high quality liquid soap, shampoo, dish wash and similar formulations. Constructed from premium 316L stainless steel, it features a double jacketed structure that supports both electric and steam heating options for precise temperature control. The liquid soap manufacturing machine integrates advanced Germany Fluko mixing technology to ensure efficient, uniform blending of ingredients. With its hygienic design, corrosion resistance, and reliable performance, this liquid soap manufacturing equipment is ideal for liquid detergent, shampoo, dishwashing and personal care production.

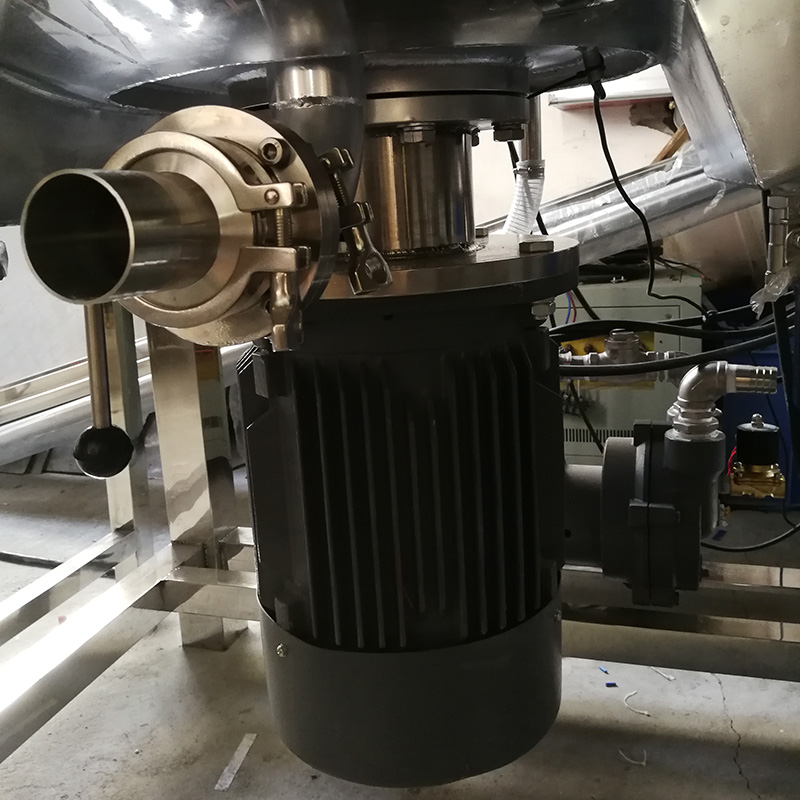

Merkevaremotor

Øvre blandemotor og bunnhomogenisator lager ganske fint og glatt produkt med høy glans. Motoren vedtar ABB- eller Siemens -merkevaren. Elektrisk oppvarming eller dampoppvarming er valgfri.

Homogenisator

Å blande, Blanding og homogent materiale når du roterer i homogenisatoren, mye brukt i industriell produksjon for emulgering, Homogenisering og blanding.

Kontrollboks

PLC -automatisk kontrollboks inkluderer temperaturkontroll, Frekvenskontroll og tidsinnstillingskontroll. Dette får deg til å redusere antall arbeid og sikre kvaliteten på produktene.

Tekniske parametere

| Kapasitet | 10-1000ML kan tilpasses |

| Struktur | MIXER MOTOR, Blandingstank, Oppvarming/kjølesystem,Elektrisk boks |

| Tank kropp | 3 Lag med blandingstank i rustfritt stål |

| Materiale | Indre lag(Materiell kontaktdel): SUS316L / tykkelse: 4mm |

| Jakke lag(Oppvarming/kjølesystem): SUS304 / tykkelse: 4mm | |

| Eksternt termisk isolasjonslag: SUS304 / tykkelse: 2.5mm | |

| Omrøringsmetode | Ved hjelp av skraping av ankertype |

| MIXER MOTOR(med frekvensomformer) Makt: 1.5Kw | |

| Rørhastighet: 0-60 Rpm | |

| Omrøring av padlemateriale:SUS316L | |

| Homogenisator | Bunntype indre sirkulasjon Homogen form |

| Homogenizer motorisk kraft:4Kw | |

| Homogenizer rotasjonshastighet: 0-3000 Rpm | |

| Homogenisatormateriale:SUS316L | |

| Åpen vei | Ensidig bærbar deksel åpent (Aktivitetsdekning) |

| Ytterligere evner | Oppvarming eller kjøling |

| Temperaturskjerm | Elektrisk oppvarmingstemperaturmåler |

| Trykk | Jakke designtrykk 0.1 MPA |

| Reservedeler | Elektrisk kontrollboks, Rør for fôring(Suge) materiale, støtteholder |

Features of Liquid Soap Making Machine

-

GMP -standard

Built in accordance with Good Manufacturing Practices, ensuring high-quality output and regulatory compliance for cosmetic and pharmaceutical applications.

-

Tyskland Fluko -teknologi

Equipped with advanced mixing technology from Germany Fluko, guaranteeing efficient, uniform, and stable product blending.

-

Tilpassbar kapasitet

Available in a range of sizes to suit small-scale labs or large-scale industrial production, tailored to your manufacturing needs.

-

ouble Jacketed Design

Designed with double-layer structure that supports both electric and steam heating for precise temperature control and energy efficiency.

-

Hygienisk design

Internal mirror polishing surfaces and sanitary fittings to ensure contamination free production, meeting stringent hygiene requirements.

Applicable Industries of Liquid Soap Manufacturing Equipment

1. Personlig pleie & Kosmetikkindustri

- Hand sanitizers & flytende såper

- Body washes & shower gels

- Sjampo & liquid conditioners

- Facial cleansers & makeup removers

- Shaving foams & geler

2. Hjem & Commercial Cleaning Industry

- Oppvaskende væsker

- Laundry detergents

- Floor & surface cleaners

- Car wash shampoos

- Disinfectant solutions

3. Hospitality & Healthcare Sector

- Hotel amenity products (bath gels, hand soaps)

- Hospital-grade hand sanitizers

- Medical facility disinfectants

- Food service cleaning solutions

4. Industriell & Institutional Applications

- Factory floor cleaners

- Vehicle cleaning products

- Agricultural cleaning agents

- Food processing sanitizers

5. Private Label & Contract Manufacturing

- Custom formula liquid soaps

- White-label hygiene products

- Boutique cosmetic cleansers

Anmeldelser

Det er ingen anmeldelser ennå.